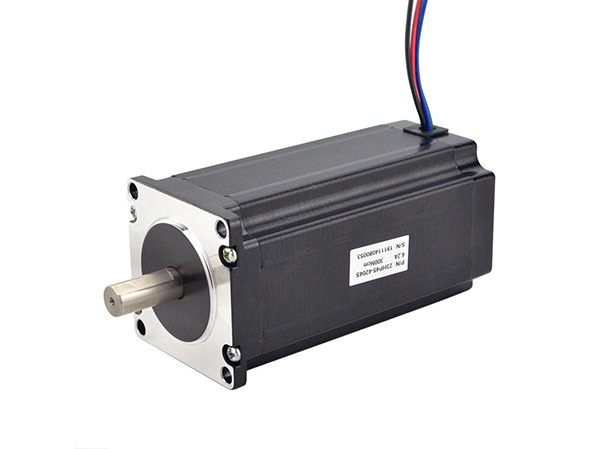

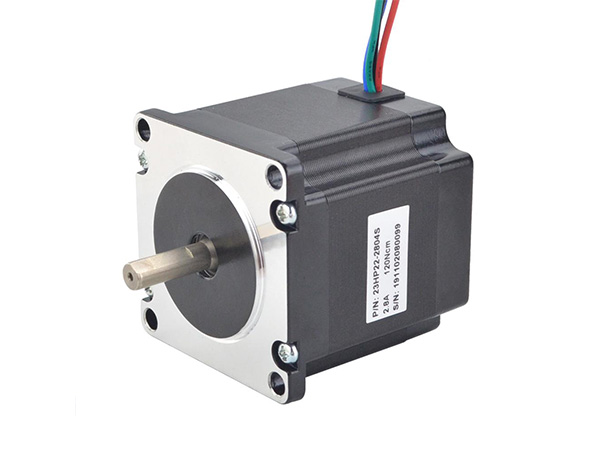

NEMA 23 hybrid stepper motoris designed by combining the advantages of permanent magnet type and reactive stepper motor. It is divided into two-phase, three-phase and five-phase NEMA 23 hybrid stepper motor, two-phase step Angle is generally 1.8°, three-phase step Angle is generally 1.2°, and five-phase step Angle is generally 0.72°.

NEMA 23 hybrid stepper motor as a digital actuator is widely used in motion control system. When using the NEMA 23 hybrid stepper motor, many users feel that the motor has a large fever when working, and they are doubtful about whether this phenomenon is normal. In fact, heating is a common phenomenon of NEMA 23 hybrid stepper motor, but what kind of heating is normal, and how to minimize the heating of NEMA 23 hybrid stepper motor?

For a variety of NEMA 23 hybrid stepper motors, the internal is composed of an iron core and winding coils. The winding has resistance, the current will produce loss, the loss is proportional to the resistance and the square of the current, this is what we often say copper loss, if the current is not the standard direct current or sine wave, will also produce harmonic loss; Iron core has hysteresis eddy current effect, in the alternating magnetic field will also produce loss, the size of which depends on the material, current, frequency, voltage, this is called iron loss. Copper loss and iron loss can be in the form of heat, which affects the efficiency of the motor. NEMA 23 hybrid stepper motors generally pursue positioning accuracy and torque output, low efficiency, current is generally relatively large, and the harmonic component is high, the frequency of current alternation also changes with the speed, so NEMA 23 hybrid stepper motors are generally heating, and the situation is more serious than the general AC motor.