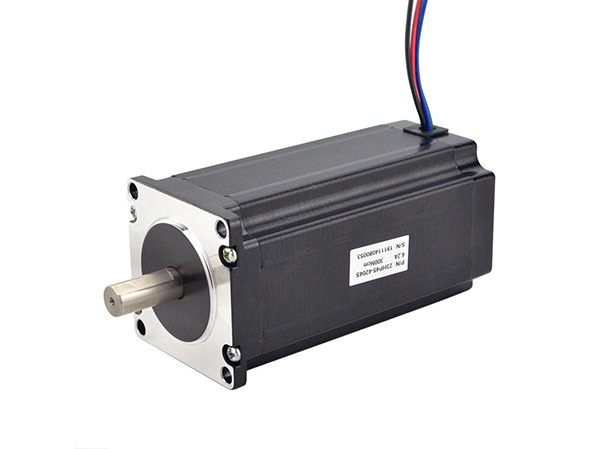

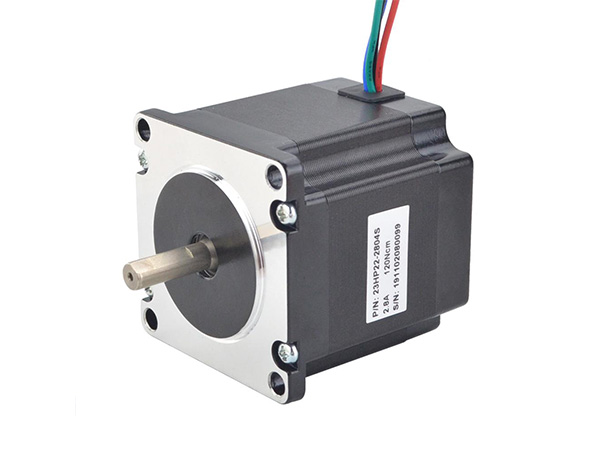

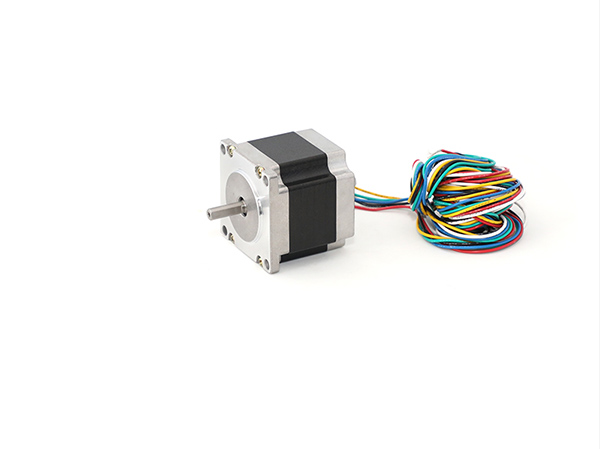

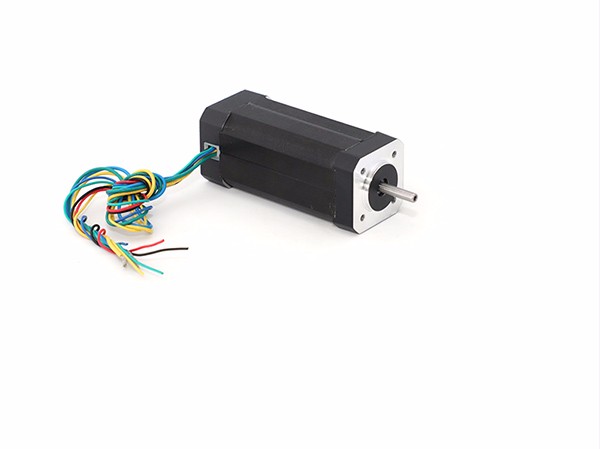

The nema 23 hybrid stepper motor is designed by combining the advantages of permanent magnet type and reactive stepper motor. It is divided into two-phase, three-phase and five-phase hybrid stepper motor, two-phase step Angle is generally 1.8°, three-phase step Angle is generally 1.2°, and five-phase step Angle is generally 0.72°.

Nema 23 hybrid stepper motor as a digital actuator is widely used in motion control systems. When using the hybrid stepper motor, many users feel that the motor has a large fever when working, and they are doubtful about whether this phenomenon is normal. In fact, heating is a common phenomenon of the hybrid stepper motor, but what kind of heating is normal, and how to minimize the heating of a hybrid stepper motor?

Nema 23 hybrid stepper motorheating allowed to what extent, mainly depends on the internal insulation level of the motor. Internal insulation is damaged only at high temperatures (above 130 degrees). So as long as the interior is not more than 130 degrees, the hybrid stepper motor will not be damaged, and the surface temperature will be below 90 degrees. Therefore, the stepping motor surface temperature in 70-80 degrees is normal. Simple temperature measurement methods are useful for point thermometers, and can also be roughly judged: touch with hands for more than 1-2 seconds, not more than 60 degrees; With the hand can only touch, about 70-80 degrees; Drops of a few drops of water quickly gasification, it is more than 90 degrees; Of course, you can also use a temperature gun to detect.

To reduce the heating of hybrid stepper motor is to reduce copper loss and iron loss. There are two directions to reduce copper loss, reduce resistance and current, which requires the selection of small resistance and small rated current motor as far as possible, for two-phase motor, can be used in the series motor without the parallel motor. But this often conflicts with the requirements of torque and high speed. For the selected hybrid stepper motor, full use should be made of the driver's automatic semi-current control function and off-line function, the former automatically reduces the current when the motor is static, the latter simply cuts the current. In addition, the subdivision driver because the current waveform is close to sinusoidal, less harmonic, motor heating will be less. There is not much that can be done to reduce iron loss. The voltage level is related to this. While high voltage-driven motors will improve high-speed characteristics, they will also increase heat. Therefore, the appropriate driving voltage level should be selected, taking into account the high speed, stability and heat, noise, and other indicators.