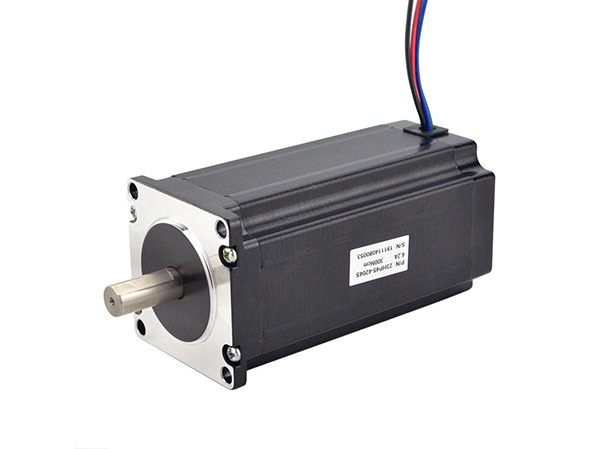

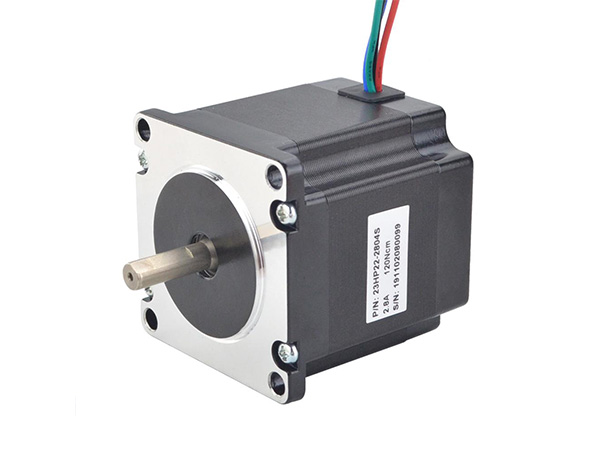

As a digital actuator,nema 23 bipolar stepper motor is widely used in the motion control systems. Many friends in the use of bipolar stepping motor, feel the motor work when the greater fever, doubt, I do not know whether this phenomenon is often. In fact, heating is a common phenomenon of bipolar stepper motors. Serious heating will affect the performance of the motor. How to minimize the heating of the bipolar stepper motor?

1, Reduce the heating of the nema 23 bipolar stepper motor, that is, reduce the loss of iron and copper. There are two directions to reduce copper loss, reduce current and electric negative, which requires the selection of motor with small rated current and small resistance as far as possible. For a bipolar stepping motor, the motor can be used in series without parallel motor, but this often conflicts with the requirements of torque and high speed.

2, For the motor, has been selected, should make full use of the driver's offline function and automatic semi-current control function, automatic semi-current control function in the motor in the static automatically reduce the current, offline function simply cut off the current.

3, In addition, the subdivision driver due to the current waveform is close to the sine wave, less harmonic, motor heating will be less. There are few ways to reduce iron loss, and the voltage level is related to this. While high voltage drive motors can improve high-speed characteristics, they can also increase heat.

4, Should choose the appropriate driving motor voltage level, taking into account the high band, stability, heat, noise, and other indicators.

For a variety of nema 23 bipolar stepper motors, the internal is composed of an iron core and winding coils. The winding has resistance, the power will produce loss, the loss is proportional to the square of the resistance and current, this is what we often say copper meteorite if the current is not the standard DC or sine wave, it will also produce harmonic loss; Iron core has hysteresis eddy current effect, in the alternating magnetic field will also produce loss, its size and material, current, frequency, voltage, this is called iron loss. Both copper loss and iron loss are expressed in the form of heating, which affects the efficiency of the bipolar stepper motor. The bipolar stepper motor generally pursues positioning accuracy and torque output, with low efficiency, large current and high harmonic component, and the frequency of current alternation also changes with the speed, so the stepping motor generally has a heating situation, and the situation is more serious than the general AC motor.